Lean manufacturing and production planning in the LPOne development vision #postblog2

Lean manufacturing and production planning in the LPOne development vision #postblog2

Link between commercial and production planning: first assertion

In this second post dedicated to Lean Production and Production Scheduling in the LPOne development vision, we will address the first assertion that must lead to the definition of concrete management objects that an ERP software should have in order to provide adequate support to modern production scheduling. Then we will talk about: Link between commercial and production programming.

Harmonising aspects of the business that are subject to constant change and adjustment and aspects that require greater stability over time is the real challenge of lean planning.

For example, primary requirements are sales orders with quantities, products and delivery dates that are subject to repeated adjustments, which are usually difficult to predict. If these products are manufactured internally, the planning of the related supplies is achieved by issuing production orders to cover them. A business item such as a production order has a strong cross-functional impact and a naturally slower dynamic than a sales order, due to various causes such as material commitments, procurement lead times and production resource loads, to name but a few.

The lean paradigm tries to solve this problem by proposing Just In Time (JIT) on the supplier side, combined with a high degree of outsourcing of both production and the stock of sub-assemblies and raw materials, while on the internal side it proposes various methods of flexibilising production (from Design for Lean Manufacturing or DFLM to One Piece Flow lines) and material handling (such as Kanban).

Far from having exhaustively listed the various lean tools and methodologies, we can however reaffirm a focus on an operation that makes the production system more dynamic, so as to be able to respond promptly to the variability of demand.

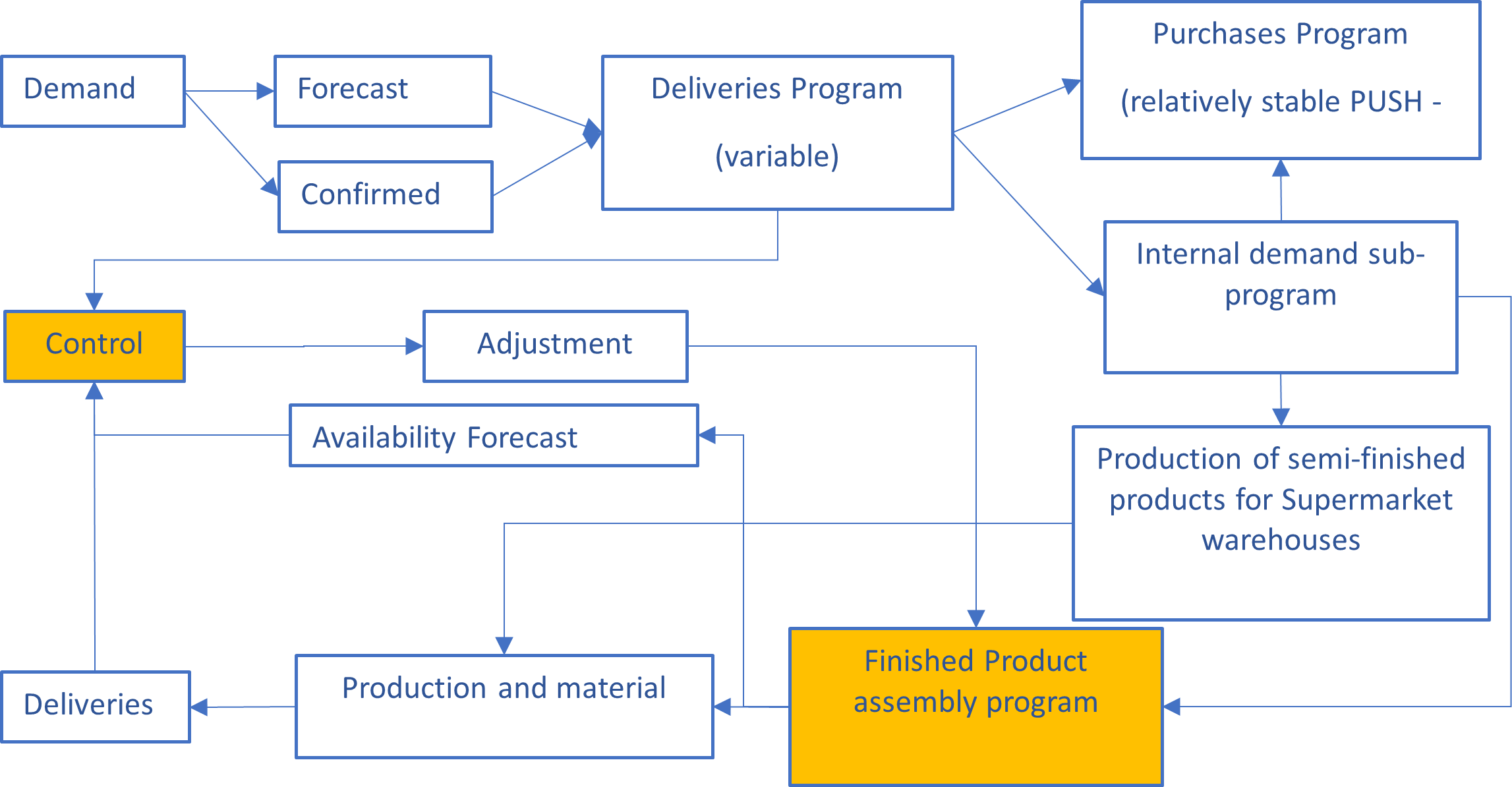

However, the reality is much more complex and fragmented! The difficult implementability of the JIT in different contexts, which would be beyond the scope of this blog, forces many companies to use a PUSH logic for the global programming of supplies and to focus only internally on a PULL logic.

It follows from the above that coordination between delivery scheduling and production scheduling must be achieved through relatively stable supply and internal demand management, achieved largely through the use of forecast demand and internal supermarket warehouses for semi-finished products.

On the other hand, the assembly part of the finished product must be subject to PULL logic to ensure rapid adaptation to the variability of deliveries. This is where DFLM and the One Piece Flow lines play an important role.mand.

LPOne implementation

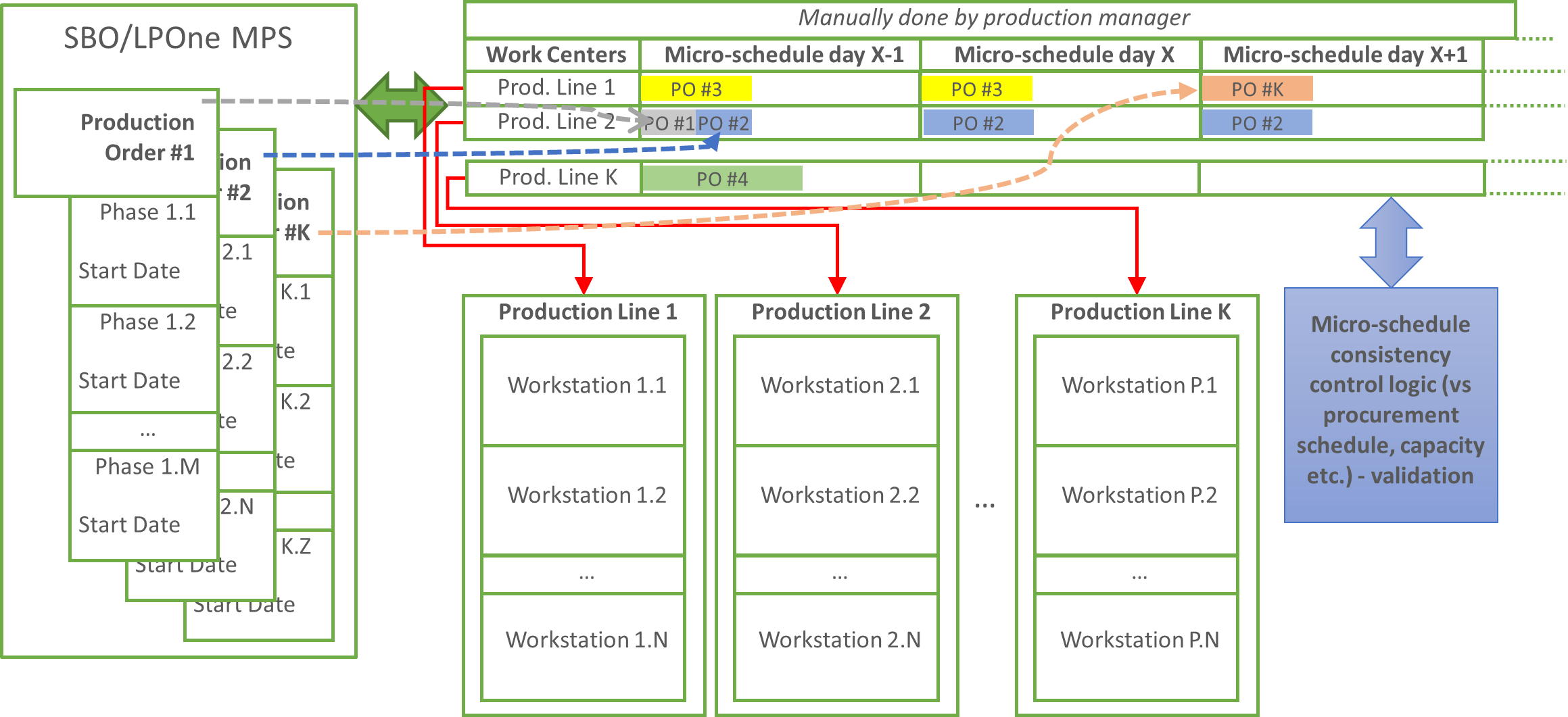

On the basis of the above, the LPOne add-on for advanced production management by InnoTech Srl features a sequencing tool, called microscheduler, through which production orders on the lines can be programmed dynamically and quickly and with the assistance of a consistency check logic, able to provide real-time information on:

- Compliance with production capacity

- Respect of delivery schedules

- Availability of materials

- Simulation scenarios

- Discrepancies between expected and planned values

Given the high degree of dynamics required, automatic planning algorithms have not been introduced, which is difficult to set up, burdensome to execute and incompatible with lean logic, plus the fact that the results are often sub-optimal and have to be adjusted manually.

For this reason, we opted for manual sequencing, but assisted by real-time algorithms capable of demonstrating its goodness.

A diagram of the microscheduling system can be seen in the figure below: