Lean Production and Production Planning in the LPOne development vision #postblog1

Lean Production and Production Planning in the LPOne development vision #postblog1

This is the first of 4 posts that will delve into the Lean Production and Production Planning vision as applied to the development of LPOne.cloud, with emphasis on the execution aspect.

The lean production model establishes a focus on the execution aspect rather than on the programming aspect of activities.

The implementation aspect has a number of rather clear and established reference methodologies such as:

- demand flow technology, which aims to develop a system capable of linking production flows directly to market demand, rather than to forecast-based planning;

- the six sigma, which focuses on continuous process/product improvement aimed at eliminating defects;

- the theory of constraints, which refers to the need for an identification of limiting strategic production factors and their resolution in global terms.

Even if we consider the TPS (Toyota Production System) model, which is one of the best known implementations of the lean or just-in-time model, we can still say that the focus is on process execution.

Despite the polarisation on the executive aspect, the Lean Model cannot disregard production planning, at different levels of scale. The scenario therefore becomes less codified and directed by “best practices” when the issue of planning is addressed.

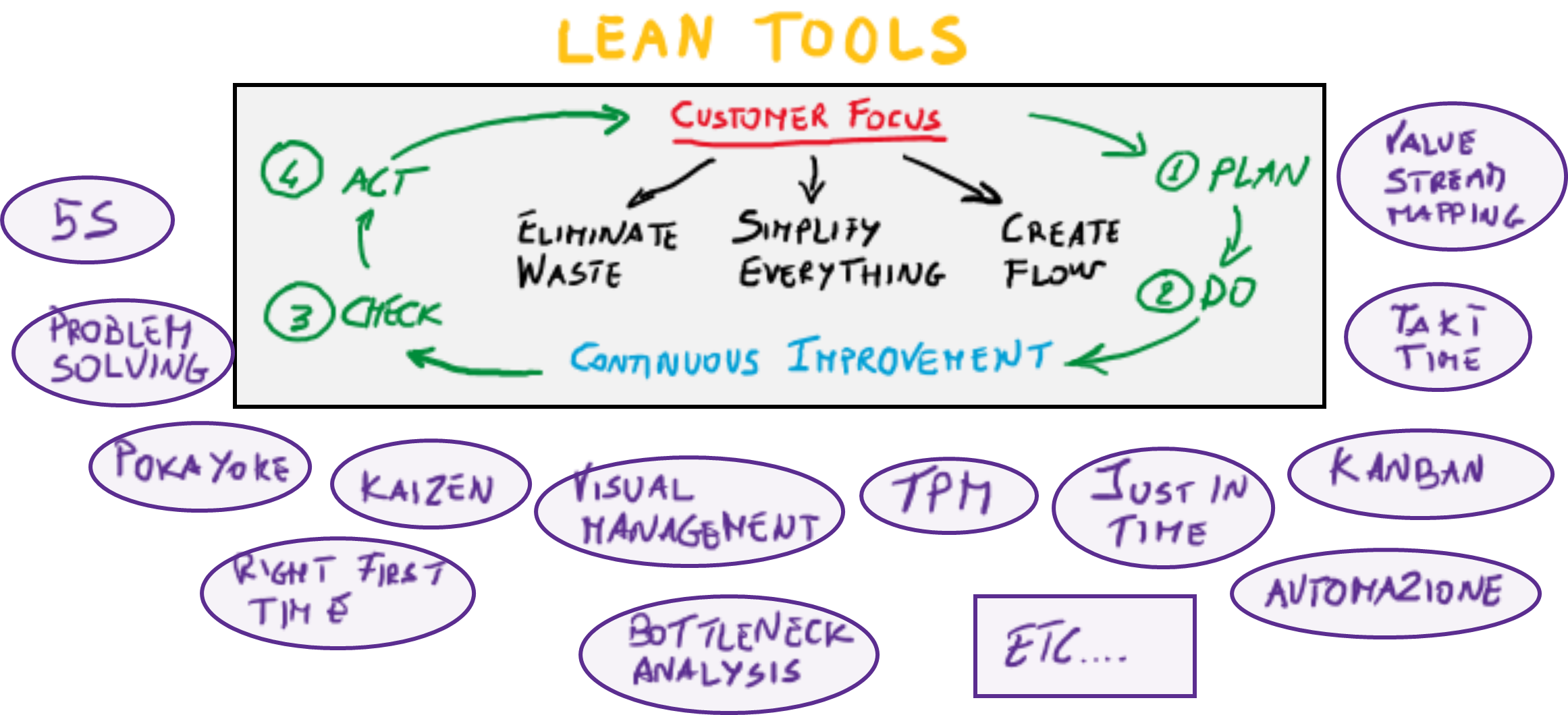

Figure 1 – Lean tools and their focus on activity execution

The word PLAN in point 1 of the PDCA (Plan-Do-Check-Act) cycle, which refers to the continuous improvement cycle and not the specific cycle of production planning, should not mislead.

So, we come to the current context of production organisation in which a well-codified lean approach still has its Achilles heel in programming practices that do not take into account fundamental aspects such as:

- Coexistence of different programming levels (sales, production, lines, etc.)

- Compatibility between aspects with different degrees of dynamics such as deliveries, which are typically very subject to change, and production orders, which require a certain degree of stability

- Presence of forecast and consolidated demand

- Presence of high production mixes, with modularity and variants to meet market needs that are becoming increasingly segmented

- Executive needs at production level that require repetitiveness, low defectiveness, streamlining and adherence to tackt time

- Lean management of deviations from the process standard (e.g. defects)

We will now try to trace the above points back to three fundamental assertions that summarise the salient aspects. The aim is to arrive at the definition of concrete management objects that an ERP software should have in order to provide adequate support for modern production planning:

- Need for a junction between commercial and production planning.

- Presence of a fast driver for selecting and configuring the line to the production mix.

- High integration with the management database of physical line devices that are crucial for the execution and automation of production steps.

These three points, with the limitations of syntheses, allow us to address the starting problem in terms of what support can be provided by an ERP system in the context of production activity planning governed by lean paradigms.

In the next few articles, we will try to go deeper into these three points in order to arrive at a set of basic functionalities that an advanced Lean production management software should have.

Massimo Landi

Product Manager InnoTech