Lean Production and Production Planning in the LPOne development vision #postblog3

Lean Production and Production Planning in the LPOne development vision #postblog3

Quick adaptation of the line to the production mix

In this third post dedicated to Lean Production and Production Planning in the LPOne development vision, we will address the second assumption that must lead to the definition of the necessary presence of a Fast Driver for the selection and configuration of the line to the production mix.

In order for a dynamic and fast micro-programming to take place, a One Piece Flow line must be able to adapt in an equally dynamic way to the production of the product variants. This can always be achieved with the use of DFLM (Design for Lean Manufacturing) and, on the management system side, with rapid retrieval of the line configuration in terms of workstations used, material used and work instructions.

LPOne implementation

Various objects and workflows are available in LPOne to allow rapid adaptation of the line to the product variant. These are listed below:

- line master data as a collection of workstations,

- line-production cycle associations,

material-workstation associations,- automatic management of material set-up,

- sending work instructions to workstations.

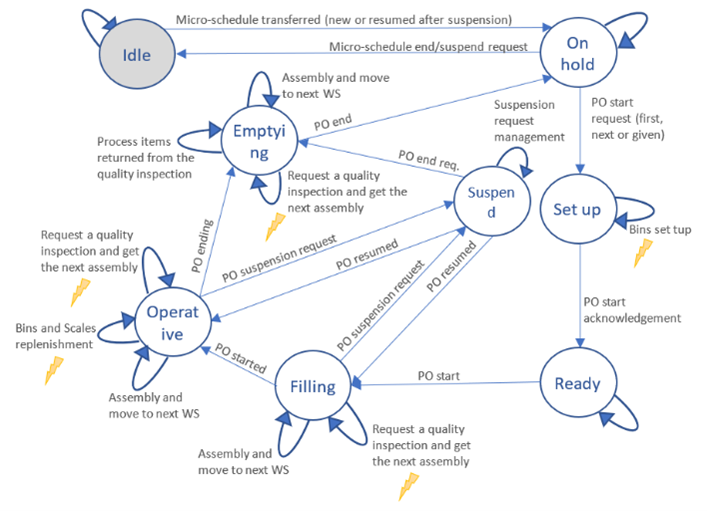

LPOne has a very powerful workflow engine, part of whose status diagram can be seen on the right, which makes it possible, with the help of specific master data and knowledge of the production sequence, to initiate and control specific phases such as line set-up and filling. Set-up data are dynamically received according to the production order being processed and concern which stations are active, the movement of material (which is to be returned to the warehouse and which is to be taken to the stations, all integrated with mobile devices and barcodes) and the operating instructions to be given to the line operators.

These functions allow very precise control right from the set-up stages and avoid errors in configuration, material presence and correctness of operations.